Our product is timeless and has great potential, due to the proven sandwich-panel properties and innovative manufacture. Usage is practically unlimited. This ranges from construction, facade and interior systems, to a mass revolution in transportation, furniture manufacture, sporting equipment and advertising spaces. Development of panels and honeycombs is carried out in our own Technological Research Institute, in cooperation with the Tomáš Baťa University in Zlín.

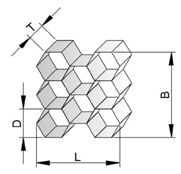

Like the core of the panels – honeycombs – we were inspired by Nature. The products must be sufficiently strong, like the honeycombs in hives. We create the cores with hexagonal cells. These are lighter and stronger than anything else available at similar prices, thanks to the material used. We are one of the few manufacturers to have our own production line for aluminium honeycomb core production. We can create customised honeycomb core, including a choice of aluminium foil thickness, cells size and specific dimensions.

| Cell size (mm) | 6 | 9 | 13 | 15 | 20 | 25 |

| Maximum expanded length (mm) | 3600 | 5400 | 7800 | 9000 | 12000 | 15000 |

| Density (kg/m3) | 70 | 47 | 32 | 28 | 21 | 17 |

| * Compressive stabilized strength (kg/m2) | 500 000 | 270 000 | 150 000 | 130 000 | 90 000 | 60 000 |

| Cell size (mm) |

Foil thickness (mm) |

Density (kg/m3) |

Compressive strength [Mpa] |

| 6 | 0,06 | 70 | 3,2 |

| 9 | 0,06 | 47 | 1 |

| E modulus of elasticity |

σfM bending strength |

dL extension |

W deformation |

| 14 300 | 43 | 0,4 | 876,45 |

| 12 600 | 44,6 | 0,5 | 1227,16 |

| 12 000 | 37,9 | 0,4 | 815,97 |

| 8 850 | 31,2 | 1,1 | 2557,52 |

| 6 800 | 207 | 0,7 | 959,57 |

| 12 400 | 47,5 | 0,6 | 1446,84 |

We arrived at aluminium honeycombs through paper ones. For over 20 years, our sister company, Forlit, a.s., has been producing lightweight, durable paper packaging materials. If you think that paper is more suitable for your purpose than aluminium, please visit our link below.

www.forlit.cz